Turning the Spotlight on carbon reduction technologies

The industry will need to accelerate investment in carbon capture technology if it is to achieve net zero by 2050. ABS, Value Maritime, Wärtsilä, ClassNK, LR and Alfa Laval are all involved in developing novel solutions to reduce carbon emissions.

Carbon capture, energy efficiency and green fuels are the roadmap to net zero by 2050. That’s the pathway outlined by the 2023 Outlook, Beyond the Horizon: View of the Emerging Value Chains – the latest industry-leading research from ABS into shipping’s progress on the green energy transition.

Released at the ABS Sustainability Summit during London International Shipping Week in September 2023, the report examines in depth the carbon, ammonia and hydrogen value chains. It concludes that the industry will need to accelerate investment in carbon capture technology, energy efficiency technologies and new fuels to achieve net zero by 2050.

“Our findings show there is a significant amount of work to be done between now and 2050 if we hope to hit net zero. But crucially, our research shows it can be done, and maps out a pathway for the industry to get there,” said Christopher J Wiernicki, ABS Chairman and CEO. “Simply put, for shipping’s CO2 emissions to reach net zero, we will need to harness the potential of energy efficiency improvement technologies to reduce aggregate fuel consumption by 15% on the existing fleet and newbuild vessels. At the same time, we will need carbon capture rolled out across much of the oil burning fleet, reducing onboard CO2 emissions by 70%. Those that do not or cannot adopt carbon capture will need to switch to e-diesel or zero-carbon biofuels.”

Vessels with conventional single-fuel engines will still be constructed until well into the next decade. As a result, widespread adoption of retrofitted energy-saving and carbon capture technologies will be required for the shipping industry to meet its targets.

2023 Outlook, Beyond the Horizon: View of the Emerging Value Chains – is the latest industry-leading research from ABS into shipping’s progress on the green energy transition

Obstacles and opportunities

The report also considers the obstacles and opportunities for adoption of alternative fuels and the actions shipowners must take in order to secure their future fuel supply chain. Growing demand for higher volumes of synthetic and green bunkers will be matched by competition for these fuels by other industry sectors.

As a result, it will be essential that shipping companies demonstrate to fuel producers that sufficient demand exists to justify investment in production, pooling their buying activity in order to secure sufficient volumes. The research highlights how shipping will play a pivotal role in the global clean energy transition.

“As the marine industry looks ahead and dives deeper into the complexities of these three value chains, the ABS Outlook makes it clear that maritime is more than a spectator in the global green energy revolution,” explains Wiernicki. “Instead, it serves as a critical facilitator and enabler. The transportation of carbon, ammonia and hydrogen as cargo highlights the industry’s significance in bridging the global energy landscape’s gaps between production, storage and consumption.”

Decarbonisation impact

The Outlook models scenarios for the impact of decarbonisation of the global economy on seaborne trade and the potential for shifting patterns of trade to reshape the global fleet. This includes falls in the aggregate share of the oil and chemical tanker and dry bulk carrier sectors and a growth in the containership sector measured in gross tonnage terms.

The transition to low and ultimately net-zero carbon operations will require substantial investment that may change the dynamic of shipping’s commercial relationships. But in the longer term, shipping operations will benefit from reduced fuel use, lower emissions, higher asset values and simplified regulatory compliance.

Considering the characteristics of the alternative fuels being considered by the maritime industry, it is clear that safety procedures and protocols as well as seafarer training will also need to evolve, the report concludes.

Carbon capture and storage installation

Value Maritime has completed the first in a series of nine installations of its emissions-reducing Filtree systems for leading product and chemical tanker company Ardmore Shipping Corporation.

Taking place in China, this was the first time that Value Maritime had installed its system outside Europe. The Ardmore Seaventure is also the first Ardmore vessel now fully equipped with Value Maritime’s Filtree system. The remaining installations for Ardmore Shipping are scheduled to take place in China over the next nine months.

Energy transition plan

In shipping, a well-defined energy transition plan can help to identify the key challenges and opportunities presented by the changing energy landscape. Ardmore’s order for nine Filtree systems is reflective of its ambitions for carbon emissions reduction and efficiency in its own fleet as well as the shipping industry at large. The company established its own Energy Transition Plan (ETP) in 2021, involving the deployment of clean technologies, innovative operational approaches, and the building of relationships with customers that are shifting their priorities towards more sustainable transportation of liquid bulk cargoes.

The plug-and-play modular Filtree system will allow for the filtration of sulfur dioxide, carbon dioxide (on further upgrade) and 99% of ultra-fine particulate matter from Ardmore’s vessels. As a result, Ardmore can continue to sail with cost-effective, performance-enhancing high sulfur fuel oil while simultaneously reducing emissions. As such, the Filtree system offers a rapid return on investment.

In a further boost for sustainability, the system features a clean loop mechanism that filters its own wash water. This removes oil residues and particulate matter and neutralises the pH value of the discharge water.

Value Maritime has completed the first in a series of nine installations of its emissions-reducing Filtree systems

Increased sustainability

Each of the nine installations on the Ardmore tankers will be carbon capture-ready to further reduce emissions. With this, the CO2 from the vessel’s exhaust can be captured and stored in onboard tanks for onshore discharge later. The captured CO2 may then be used in a sustainable manner, for example in the agricultural and food industries.

This facilitation of carbon capture and storage comes at an opportune moment. The Value Group (Value Maritime and Value Carbon) recently announced that Shell Ventures had joined its investor board to accelerate and expand the group’s carbon capture utilisation and storage strategy.

“We’re really pleased to have successfully completed the first in this series of installations for Ardmore,” explains Yvette van der Sommen –

Commercial Director, Value Maritime. “This represents a milestone moment for Value Maritime as the Filtree system makes its debut outside of Europe. We’re very proud to see this expansion, which is an indication of the relevance the system has in helping vessel operators to reduce their emissions We’re very much looking forward to our ongoing collaboration in future installations.”

Anthony Gurnee, CEO of Ardmore, says: “At Ardmore, our approach to the energy transition is underpinned by the mindset that shipping’s progress towards decarbonisation is an evolution over time. While the industry continues to make regulatory progress away from carbon-intensive practices over the long term, the development and utilisation of short-term solutions like Value Maritime’s Filtree solution, as well as many other technologies we have adopted, is as crucial as it is broadly applicable across all shipping sectors. The Filtree solution is exceptional in that it not only cleans and neutralises overboard discharge but also offers an additional benefit in the form of a potential carbon capture upgrade. This gives us flexibility today while economically future-proofing our vessels and creating commercial opportunities for us tomorrow.”

Carbon capture and storage feasibility studies

Technology group Wärtsilä is now offering carbon capture and storage (CCS) feasibility studies to shipowners and operators, in another milestone on its journey to research, develop and bring to market maritime CCS technologies. The studies have already been conducted on a range of vessel types including RoRo and RoPax vessels, a drill ship, a container vessel and a gas carrier.

The process takes four to six months of study and design work. Wärtsilä Exhaust Treatment’s experts are involved in ship design at an early stage to conduct engineering work to understand how CCS can be smoothly integrated once the technology is launched to market.

Wärtsilä is conducting the feasibility studies across both newbuild and existing vessels. Retrofit CCS installations will be significantly smoothed by the presence of a scrubber onboard. Wärtsilä Exhaust Treatment is already offering CCS-Ready scrubbers to the market, which are integrated onboard in a way that enables a CCS system to be added easily in the future once the technology is commercialised.

Once completed, the CCS feasibility study work enables Wärtsilä to provide customers with a fully rounded commercial offer that can be shared with shipyards to get an exact quote for installation. During the feasibility studies, Wärtsilä’s experts closely examine the existing naval architecture of the ship and work to understand how the power, space and exhaust demands of CCS can be accommodated onboard. Owners will receive a qualified analysis of the costs of CCS integration, and a clear list of considerations on how a potential retrofit would be conducted in the least intrusive way.

Wärtsilä is now offering carbon capture and storage (CCS) feasibility studies to shipowners and operators

CCS integration

Conducting the studies today enables Wärtsilä to bring forward the early stages of CCS integration and, in doing so, lower the barrier to entry once the technology is commercialised in the near future. The studies also serve to educate customers on the upsides and particular considerations associated with installing CCS onboard their vessels. Finally, as the studies will run in parallel with the implementation of new environmental regulations for shipping, owners who conduct them today will be ‘ahead of the curve’ versus their peers.

“Launching these feasibility studies and being able to offer them to market is the exciting latest step in our process of bringing carbon capture and storage to market in shipping,” explains Sigurd Jenssen, Director, Wärtsilä Exhaust Treatment. “It builds on the market-leading work we are conducting in our test hall in Moss, where our technology is already demonstrating our targeted 70% capture rate, and enables us to directly engage with customers to smooth the CCS adoption process in the near future.”

Jenssen continues: “By conducting these studies today, we are already building a considerable track record and understanding of how this technology will work across multiple vessel types. It builds on the considerable uptake we have already seen for our CCS-Ready scrubbers, which show that the industry is not only exploring CCS as a speculative technology, but is actively investing in its foundations as a decarbonisation solution. We look forward to conducting more of these studies in the coming months as we work to bring our CCS system to market.”

Smooth integration

When a customer opts for a Wärtsilä CCS-Ready scrubber, the company takes measures during the scrubber installation process to ensure adequate space for the future installation of CCS system. CCS-Ready scrubbers are also designed to enable smooth integration with a particulate matter filter.

Wärtsilä Exhaust Treatment is the market-leading marine exhaust gas cleaning system manufacturer, with a range of lifecycle solutions. Wärtsilä offers integrated compliant solutions for all types of ships, and in open loop, closed loop or hybrid configurations. Wärtsilä’s scrubbers are built with a modular approach to future technology development, creating a platform for the abatement of other emissions from shipping beyond sulfur.

OCCS approval

ClassNK has issued an Approval in Principle (AiP) for an onboard CO2 capture and storage (OCCS) system developed by China Shipbuilding Power Engineering Institute Co, Ltd. (CSPI), a member of CSSC Power (Group) Co Ltd (CPGC).

In addition to fuel transition, interest in capturing CO2 from ships’ exhaust gas is growing as a way to reduce GHG emissions. This is driving the development of onboard systems for capturing and storing CO2. To encourage the development of the related technology, ClassNK has published Guidelines for Shipboard CO2 Capture and Storage Systems, including safety requirements for the systems and their installation on ships.

For a design concept of the system developed by CSPI, ClassNK conducted a review based on Part D (Machinery) of its Rules and Guidance for the Survey and Construction of Steel Ships and Guidelines for Shipboard CO2 Capture and Storage Systems. Having verified the system drawings, risk assessment results, etc, ClassNK issued the AiP upon confirming compliance with the prescribed requirements.

“The current global shipping decarbonisation goal is accelerating, and CPGC is actively responding to the trend by developing OCCS, which has high efficiency, high integration, and low energy consumption,” explains Dai Qun, Deputy Section Chief/Senior Engineer, CPGC. “The AiP of OCCS issued by ClassNK for CPGC will provide assistance for us to achieve the transformation and development of green and low-carbon ship power.”

“Onboard CO2 capture is one of the potential solutions for pursuing decarbonisation, along with the transition to alternative fuels,” says Masaki Matsunaga, Corporate Officer/Director of Plan Approval and Technical Solution Division, ClassNK. “We are pleased to issue the AiP for the forward-looking design concept of the system developed by CSPI. ClassNK remains committed to supporting the realisation of innovative solutions for the decarbonisation of shipping.”

LNG fleet decarbonisation

Lloyd’s Register (LR) and Shanghai COSCO Shipping LNG Investment (COSCO), a subsidiary of China Shipping Corporation Limited, have signed a partner agreement for the intention of a new project that aims to formulate and assess the decarbonisation pathway for COSCO Shipping’s existing LNG carrier fleet.

The intention was signed formally with a Letter of Intent at Gastech 2023 and will focus on providing COSCO with insights to enable them to make its existing fleet of LNG carriers carbon neutral by 2040.

As part of the project, LR will support an analysis of COSCO’s fleet operations characteristics and carbon emissions, looking at future carbon reduction energy transition practices alongside future fuels, energy efficiency technology and retrofit plans.

The intended project would see the further development of COSCO’s fleet capacity, future energy adoption and efficiency transformation, based on the shifting landscapes of world trade and shipping companies’ development planning.

Open collaboration

“The decarbonisation of our industry is going to require open collaboration between the entire maritime value chain,” explains Sau Weng Tang, Lloyd’s Register Commercial Manager – Greater China. “This is why projects and partnerships like this are so important, they provide an opportunity for fleet operators to thoroughly analyse the options available to them to enable them to reach their own and industry-mandated requirements for maritime decarbonisation.

“LR is proud to work alongside one of the key players in the LNG sector in COSCO, and we look forward to providing our technical expertise as a trusted adviser on this project to ensure COSCO can successfully navigate their journey towards a carbon neutral fleet by 2040.”

Lin Nan, GM, COSCO Shipping LNG Investment (Shanghai) said: “In the context of IMO maritime decarbonisation strategy, CSLNG, as an international LNG shipping company, will endeavour to fulfil the responsibility and accountability to achieve our LNGC fleets’ carbon reduction and provide low-carbon and efficient LNG transportation services for the industry. In this effort we appreciate valuable cooperation between the industrial chain, including the open support from the expertise of LR.”

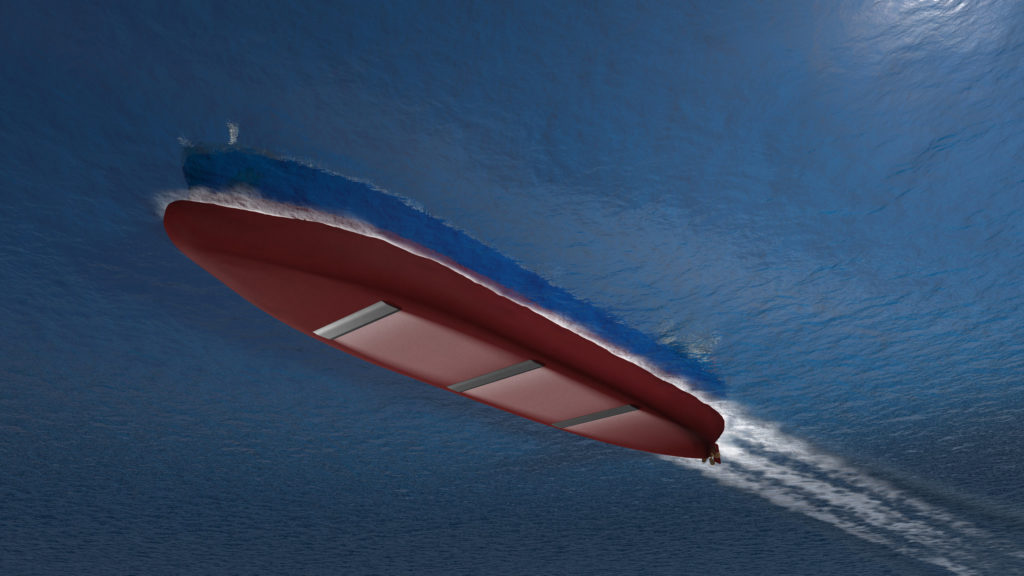

LPG tanker air lubrication retrofit

Kumiai Navigation (PTE) Ltd has selected Alfa Laval OceanGlide to be installed on one of its LPG tankers as a retrofit. Kumiai’s decision to leverage fluidic air lubrication technology is rooted in its ambition to reduce the vessel’s energy consumption, improve its overall performance and comply with environmental regulations.

The OceanGlide fluidic air lubrication system is to be installed on a 54,000dwt LPG tanker owned by Kumiai Navigation, a Southeast Asian LPG tanker and bulk carrier company. With this order, Alfa Laval has added LPG tankers to vessel types that can benefit from the OceanGlide system. The system can be installed on both new and existing ships with ease.

Kumiai Navigation (PTE) Ltd has selected Alfa Laval OceanGlide to be installed on one of its LPG tankers as a retrofit

Trusted partner in the sustainability journey

As shipowners worldwide navigate the dynamic landscape of maritime sustainability, Alfa Laval OceanGlide offers a uniquely efficient and easy-to-install air lubrication solution. This patented system uses fluidic technology to generate an even, controllable air layer across a vessel’s entire flat bottom, reducing friction and drag. By decreasing the vessel’s resistance, OceanGlide offers a proven method for reducing fuel consumption and CO2 emissions.

“In these challenging times, we recognise that reliable partners such as Alfa Laval are needed to achieve our sustainability goals,” says Tomo Kuroyanagi, Managing Director, Kumiai Navigation. “We want to invest in green shipping practices to help us lower our power consumption and comply with upcoming environmental regulations. In this effort, OceanGlide fluidic air lubrication is currently one of the best available solutions that offer remarkable gains in improving vessel performance and meeting our environmental targets.”

The decision to choose OceanGlide originates from the customer’s ambition to reduce the vessel’s energy consumption and emissions, coupled with the company’s trust in Alfa Laval’s solution to make a significant impact on the vessel’s carbon footprint.

“We are pleased to partner up with our customer, Kumiai Navigation, to serve the LPG tanker segment with our fluidic air lubrication system, OceanGlide,” says Rajiv Sarin, Head of Air Lubrication, Alfa Laval. “We value the trust our partner has in our technology and collaboration to help them achieve their goal of sailing sustainably. As the market for OceanGlide fluidic air lubrication grows, we are happy to support our customers in their efforts to reduce CO2 emissions and improve energy efficiency of their fleet as a retrofit or a new build installation.”

Alfa Laval’s OceanGlide system

Proven technology with multiple benefits

OceanGlide uses fluidic technology to create and control streamlined air layer sections on the vessel’s flat bottom, each with its own fluidic band. The independent steering of each band allows a more controlled airflow to reduce friction between the hull and water. These individually-controlled sections serve to minimise drag and ensure maximum coverage, eliminating passive cavities along the vessel’s underside.

Energy expenditure is minimised because there are few compressors and the bands add almost no drag when switched off. Air distribution bands are installed easily with minimal hull penetrations, which reduces shipyard time and costs, even as a retrofit.

OceanGlide is proven to reduce specific drag by 50-75% and can provide reliable fuel savings of up to 12% under real-life conditions. The actual amount of fuel savings achieved can vary depending on vessel operations and operator priorities.

The technology also supports compliance with EEDI/ EEXI and CII requirements laid down by the International Maritime Organization (IMO) to reduce greenhouse gas emissions.

“OceanGlide serves our goal of adopting advanced new sustainable technologies to remain competitive in this challenging market. We are excited to take advantage of the fluidic air lubrication technology to help us decarbonise and contribute towards our carbon reduction roadmap,” says Kuroyanagi.

Read more articles like this in the latest issue of DryDock magazine.