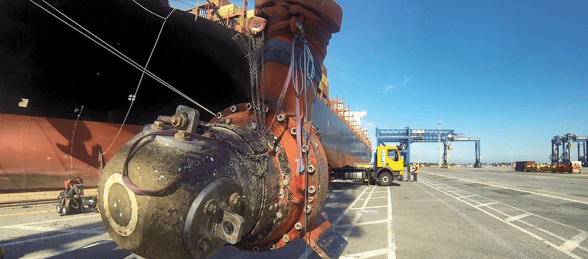

A month after Hydrex divers removed the bow thruster of a 300-meter container ship they once again mobilized to Italy. They reinstalled the overhauled unit underwater with the use of the company’s flexible mobdock technique.

The available time window for the removal of the bow thruster had been very short because of the tight schedule of the vessel. For this reason the job was split in parts, performed in different ports.

The time frame for the reinstallation was slightly larger, allowing the team to carry out the job during a single stop of the vessel. The divers used the flexible mobdocks to close off the thruster tunnel once the overhauled bow thruster had been brought into the tunnel.

All water was removed from the tunnel. This created drydock-like conditions for the divers while the vessel stayed afloat. The team then secured the unit and connected it. Once this was done the thruster propeller blades were installed one by one. With these in position the ship was ready to sail.

The Hydrex team worked in shifts around the clock to finish all tasks as fast as possible. As a result the charterer did not have to worry about his vessel’s schedule.

Replacement in stages keeps cruise ship on schedule

A 208-meter cruise vessel sailing in the Caribbean suffered steering problems after one of its two bow thrusters malfunctioned. Having to depend on assistance every time the ship berthed would quickly become very expensive. Going off-schedule, however, to have the bow thruster replaced would cost the owner both in finance and reputation.

A solution was therefore needed that could be carried out on-site without interrupting the vessel’s schedule. Enter the Hydrex tried and tested flexible mobdock technique and experienced diver/technicians.

There was only a time frame of eight hours at each port of call during the ship’s cruise in the Caribbean. It was therefore important that the operation was split up in parts that could be finished before the vessel had to leave again. A perfect planning and constant communication between the Hydrex technical department in the office and the team on location was essential in achieving this.

Underwater bow thruster operation on Ferry in Oslo

Recently a team of Hydrex diver/technicians mobilized to Oslo, Norway for an underwater bow thruster operation on a large ferry. A seal in the gearbox was leaking and needed to be replaced. A small window was made available for the operation, but the repair had to be finished before the next scheduled trip.

The Hydrex technical department proposed to replace the defective seal underwater with a tailor-made cofferdam. The cofferdam was designed by their R&D department and fabricated at the Hydrex headquarters in Antwerp. This allowed the divers to remove the damaged seal ring and replace it with a new one in a dry environment.

Flexibility is an important element of every job Hydrex carries out, but in this case it was crucial that the repair was finished before the ferry needed to depart with its passengers.