The SS Nomadic back at H&W, A&P setting records, a Pole Star at Rosyth, a strong 2020 for Cammell Laird, a midlife upgrade at Damen, and busy Remontowa and SMS

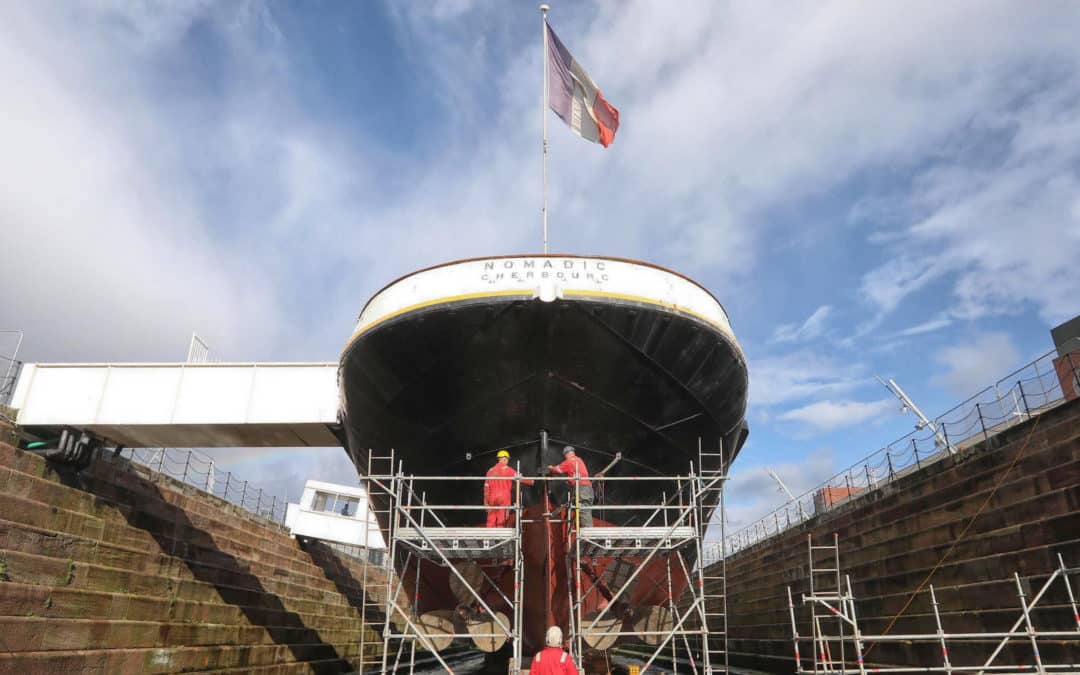

The SS Nomadic, the ship which took passengers to RMS Titanic from Cherbourg Harbour, is undergoing restoration works this month which will be carried out by its original builders, Harland & Wolff. Titanic Foundation, the charity set up to preserve and promote Belfast’s maritime and industrial heritage including the development of Titanic Belfast, owns the tender to RMS Titanic and appointed Harland & Wolff to carry out the works on the ship that they completed in 1911.

The SS Nomadic is now included in the Titanic Belfast Experience, giving visitors the chance to step onboard the world’s biggest RMS Titanic artefact. A quarter of the size of the iconic passenger liner, the Nomadic has many of the same ornate features and finishes and was completed in 1911.

As the last remaining White Star Line ship, SS Nomadic requires continuous maintenance and restoration. The works taking place in October will see repairs to the keel blocks supporting the ship, which is located in the Hamilton Dry Dock. Harland & Wolff also carried out restoration works on the ship in 2011 after it returned to Belfast, reinstating the bridge deck, flying bridge desk and the funnel.

“The SS Nomadic is such an authentic part of Belfast’s maritime history and a fantastic feature on the Maritime Mile, said Kerrie Sweeney, Chief Executive of Titanic Foundation. “To have Harland & Wolff return to carry out work on the ship they once built is a really significant moment in the history of the ship.”

Perry Kennedy, Interim Managing Director of Harland & Wolff commented,

“We’re very excited to begin work on this iconic ship once more. As the original builders, this is a great opportunity to continue our proud heritage alongside the Titanic Foundation.”

A&P Falmouth registers a record

A&P Falmouth will welcome a record number of vessels this October as the facility repairs, refits and maintains nine vessels and all three drydocks are full.

A total of five vessels will use A&P Falmouth’s drydock facilities, two of which will be double dockings. The German container ship, Samskip Express will enter Dock Two for a series of hull repairs from grounding damage, followed by Tarmac’s City of Chichester dredger, which undergoes standard maintenance and repairs each year.

Dock Three will welcome Serco tugs SD Careful and SD Deborah simultaneously for their standard dockings, while Dock Four will play host to Condor Ferries’ Commodore Goodwill as part of its Commercial Partnership Agreement with A&P.

Four vessels – RFA Mounts Bay, HMS Tamar, HMS Trent and P&O Ferries’ Pride of Burgundy will also undergo refit works, general maintenance and mobile repairs while alongside in Falmouth.

Busy month

“October will be a very busy month for A&P Falmouth as we have a full house of ships and all aspects of our facility will be in constant operation,” says Andrea Sabbion, Business Development Director at A&P Falmouth. “The arrival of Ro-Ro passenger vessels, container vessels, dredgers, military vessels and tug boats shows the diversity of our expertise and facilities. This also reflects the strength of our order book and a degree of pent up demand caused by the pandemic. Careful pre-planning and schedule management has enabled us to counter some of the challenges of the last few months, particularly in relation to the supply of critical spare parts.

“The team has also adapted quickly to our new stringent HSEQ measures to mitigate the risk of Covid-19 and keep our clients safe. It’s thanks to them that we’ve been able to remain operational for our clients during this time.”

A&P Falmouth is part of A&P Group – a leading provider of ship repair, conversion and marine services and heavy engineering expertise, which operates seven drydocks and extensive fabrication facilities across three strategic locations in the UK.

As one of the leading engineering business in the UK, A&P is involved in a diverse range of fabrication and repair projects across a broad cross section of sectors including Defence, Marine, Oil and Gas, Subsea, Energy, Civil and Nuclear. High profile projects have included delivering block build fabrication for the Astute Submarine Class, HMS Queen Elizabeth Aircraft Carriers and RRS Sir David Attenborough, as well as fabricating pontoons and sea fastenings for the offshore wind sector.

All A&P Group facilities combine a rich heritage of marine and engineering skills and experience, providing a diverse customer base with all the precision skills needed to complete the most demanding projects.

Pole Star arrives at Rosyth

Babcock International, the Aerospace and Defence Company has successfully completed a package of work for the Northern Lighthouse Board following a competitive tender process. NLV Pole Star, a vessel designed to deploy and maintain buoys and respond to wrecks and new dangers to navigation, arrived at Babcock’s Rosyth facility last month for repair, maintenance and safety checks. This follows a similar package of work on sister vessel, NLV Pharos earlier this year. The work builds on a busy period of similar programmes at Rosyth for a growing number of customers.

With its proven track record of delivering engineering excellence coupled, with extensive facilities and capabilities at Rosyth, Babcock provides the ideal support for the Northern Lighthouse Board, the body responsible for the operation of lighthouses and marine navigation aids around the coasts of Scotland and the Isle of Man.

Both Pole Star and Pharos operate mainly in Scottish and Manx waters, servicing over 200 automatic lighthouses, buoys and beacons. Ensuring the vessels are maintained, fit for purpose and safe, is paramount for them to carry out the necessary work around some of the UK’s most dangerous coastlines.

A team of 50 Babcock employees and contractors worked on the general upkeep package which included replacing the hull valves, hull repair, overhauling of the ships cranes, replacement of anodes and restoring and painting the vessel to a high standard.

“We were pleased to welcome the Northern Lighthouse Board as a new customer to Rosyth and work with them to successfully and safely complete the engineering upkeep on NLV Pole Star and NLV Pharos,” said Sean Donaldson, Managing Director at Rosyth. “Our team worked well together to deliver and I am delighted to see NLV Pole Star leave the site for sea trials in the best possible material state.”

Supporting this extensive package of work included a team of specialists consisting of welders, fabricators, mechanical fitters, projects controls, production management and contractors.”

Graham Moffat, Technical Superintendent with the Northern Lighthouse Board said:

“As an organisation dedicated to the safety of those at sea, it is of upmost importance that our own vessels are rigorously checked and maintained to the highest standard, so that we can continue to serve the mariner and keep our own people safe in Scottish and Isle of Man waters.”

Strong 2020 for Cammell Laird

Merseyside shipyard and marine engineering services company Cammell Laird has reported a strong 2020, despite the challenges of Covid-19, with its construction hall, workshops and dry docks in continuous use since the start of the year.

Speaking about operating during a global pandemic, the CEO of Cammell Laird, David McGinley said: “Despite the restrictions and challenges of the last few months, the needs of our clients have not changed, and we have seen consistent demand for our engineering expertise and on-site facilities.”

“The team has shown fortitude, commitment and agility throughout, which has been instrumental in keeping clients’ vessels operational and maintaining our reputation for engineering excellence.”

Projects of note during 2020 have included achieving a series of important milestones in the construction of RRS Sir David Attenborough – the research ship that will transform how ship-borne science is carried out in the Polar Regions.

Cammell Laird has tested and commissioned the vessel’s lifeboats and power systems and most recently, the water mist fire protection system. Work is now focused on readying the vessel for sea trials in October, which includes commissioning and testing the marine propulsion systems as well as checking the vessel’s scientific underwater sensors and deployment mechanisms.

Other notable projects include the ongoing transformation of unique cargo-passenger ship RMS St Helena, as she becomes a mobile hub for the Extreme Electric SUV racing series. Cammell Laird is also preparing for the start of the next ferry season, which will see the return of all four Calmac Ferries for their annual maintenance periods.

First Type 45

Focusing on Cammell Laird’s roster of defence work, the yard has welcomed the first of the Royal Navy’s Type 45 class of destroyer to Birkenhead. HMS Dauntless is undergoing her Power Improvement Programme (PIP), which will improve the resilience of the power and propulsion systems by replacing two diesel generators with three new systems and modifying the high voltage system.

Cammell Laird is also in the final stages of a 10-month programme of equipment upgrades and general repairs and maintenance for RFA Tidesurge, the third of the RFA Tideclass tankers, as part of a Through Life Support contract to maintain nine RFA vessels over the next 10 years.

Upgrades included the installation of four new 40m long exhaust systems, complete with new structural steel. A series of precision lifts were required to transfer the new exhaust system, including its 3.5 tonne silencers, into the engine room via the vessel’s funnel. The team is also upgrading the fire main (HPSW) and making improvements to the ballast water treatment system.

Parts of the vessel’s Azimuth bow thruster will also be replaced, the preparation for which involved digging a five-metre pit to accommodate the four-metre diameter thruster tunnel as it is removed prior to changing out the 5m main support tube. While in the dry dock, the sea valves, rudders and propellers will also be inspected and serviced.

The former Project Director for the RFA Tideclass tankers at Cammell Laird (now with Type 45 PIP), Tony Scaife said: “Working to the vessel’s design intent and using our learnings from the previous Tideclass vessels, we are delivering a complex programme of work to a very high standard. It’s testament to the depth of our experience and project management skills, as well as our relationship with the Ministry of Defence, that we are able to do that.”

RFA Tidesurge is expected to depart Cammell Laird in December before RFA Tideforce arrives in early 2021. Other ongoing defence projects include wave-class fast fleet tanker RFA Wave Knight, which is nearing the end of a £14m refit programme of upgrades, servicing and refits.

RFA Wave Knight arrived at Cammell Laird in March, following a six-month deployment in the Middle East and spent eight weeks in Cammell Laird’s Dry Dock number five, before being moved to the South Berth West Basin. The programme includes hull and tank surveys; service, inspection and repair of the mooring winches; renewal of the cargo tank PV valve pipework, refurbishment of the ABEAM RAS rig equipment; a repaint of the vessel’s hull and super structure and renewal of the flight deck coating.

Bolstered management

During the last six months Cammell Laird has also bolstered its senior management team, with hires and appointments spanning operational, health, safety, environment and quality (HSEQ), procurement and commercial roles.

Linton Roberts, Cammell Laird’s former Group Technical Director of Sales has been appointed as Director of Operations, while Kevin Peart, formerly Group HSEQ Director of A&P Group, has been appointed as Director of HSEQ for both Cammell Laird and Atlantic and Peninsular Marine Services. Former Head of Procurement, Jane Bryan assumes the role of Director of Procurement, Steve Gibney acts as Interim Director of HSEQ and Neil Harden joins as Director in the commercial team from MJ Quinn.

A midlife upgrade at Damen

HNLMS Pelikaan is back again in the familiar waters of the Caribbean after Damen Shipyards Den Helder redelivered the vessel to the Royal Netherlands Navy (RNLN) following a mid-life upgrade lasting eight months. Following the work, the vessel, which Damen originally delivered to the RNLN in 2006, is ready for a further 15 years’ service.

The end of November 2019 saw the Caribbean support vessel return to the Dutch coast for the first time since she was put into service in 2006. After operating for thirteen years in the Caribbean Sea in support of maritime operations and in the delivery of humanitarian relief, it was time for major maintenance works, which took place at the Damen yards in Den Helder and Harlingen.

Works carried out included installing new nautical, communication and automation systems, galley upgrade and regular maintenance such as maintenance of the two main engines. The most important upgrade was the installation of a considerably heavier crane, the main weapon system of HNLMS Pelikaan. This crane is crucial for, among other things, being able to independently carry out emergency relief operations in the Caribbean. The crane is not only considerably heavier, more modern and more user-friendly than its predecessor, but it also facilitates the use of a new fast raiding interceptor and special forces craft (FRISC). This fast and manoeuvrable craft enables HNLMS Pelikaan to act more effectively in the fight against drug smuggling. The scope of work also involved the renewal of all onboard accommodation, including making the vessel more suitable for female passengers.

“The project was not without its challenges – including of course the outbreak of the coronavirus,” explains Project Leader, Jan-Dirk Boomsma. “However, with robust safety measures in place we were able to continue the work. Thanks to the excellent cooperation with the Defence Materiel Organisation (DMO), the Naval Maintenance and Sustainment Agency (DMI) and the crew, we delivered the project to everyone’s satisfaction in a relatively short period of time.”

The midlife upgrade was successfully realised, partly in close collaboration with the Dutch naval shipbuilding cluster. Alewijnse, Heinen & Hopman, Alfa Laval, Hatenboer Water, Rohde & Schwarz are a small selection of the Dutch subcontractors who took part in this project.

Harlingen completes ferry repair project

Damen Shiprepair Harlingen (DSHl) has recently completed a repair project to Rederij Doeksen’s passenger/car ferry Vlieland. The vessel operates a ferry service across the Wadden Sea between Harlingen in the north of the Netherlands and the island of Vlieland.

The Vlieland required repair following a recent incident that took place as she was departing the harbour in Harlingen. As a result of the accident, the vessel’s SB engine room became flooded. DSHL carried out an emergency operation, closing the hole, before moving the vessel on to the yard for full repairs.

At the yard, DSHL carried out a series of works on the vessel, including the removal of the main and auxiliary engines, the gearboxes and all electrical equipment and wiring – of which there is over 4km. Following this, the yard undertook the rebuilding of the engine room. This included re-installing the CAT 3508 main engines and Cat 3406 & 3408 auxiliary engines cpl/w generator sets that had been overhauled by PON. Klaas Krook account manager product support at PON explained, “We value our relationships, most of which are long-term. When Doeksen was faced with the damage on the Vlieland, we went the extra mile. Together with our valued partner Damen, we overhauled the engines in the SB engine room, and used Reman parts to get it done cost efficiently.”

At the same time, the yard blasted the hull and repainted the vessel. A local company, electrical technicians Piet Brouwer, installed a new monitoring and safety system on the Vlieland – Rederij Doeksen having decided to take the opportunity to do so while the vessel was in dock.

Damen Shiprepair & Conversion Sales Manager, Klaas Kuper says, “Rederij Doeksen is a long-standing client of Damen Shiprepair Harlingen, visiting the yard on a regular basis for the scheduled maintenance of their fleet. We enjoy an excellent relationship and are pleased to be able to assist them in getting the Vlieland safely operational again.”

Richard de Vries, manager operations at Rederij Doeksen said: “We are pleased to be able to take Vlieland back into active ferry service. We are very satisfied with the cooperation between the various parties, who have made every effort to get this job done as quickly and professionally as possible.”

Remontowa steps up remote survey techniques

Remote surveillance techniques for ship repairs during the COVID-19 pandemic

The repairs of the Star Stratos reefer and the YM Express container ship are examples of ships serviced in Remontowa remotely, without the need of personal surveillance of the shipowner’s representative.

The reefer, Star Stratos, (Nissen Kaiun Co. Ltd.) called at Remontowa in the second quarter of 2020. Due to the COVID-19 pandemic, the shipowner could not use the services of his superintendent. However, he decided to hire his representative on site. After last year’s installation of the BWT system, this year a scrubber was installed on the ship. Before she arrived, an additional section, the so-called scrubber house, (i.e. the high room in which the scrubber is placed), had been prefabricated in the yard. When the ship was already in the shipyard, the ready-made section with the scrubber installed inside, was transported to the ship and installed at the stern. The ship was also drydocked to undergo maintenance and painting of its hull.

Nordic Giant and Spirit

In the second quarter of this year, the shipyard repaired two vessels belonging to Royal Boskalis BV – the Nordic Giant backhoe dredger and the Spirit cable-laying vessel.

The Nordic Giant was mainly in for hull works, with maintenance and painting works being carried out on the hull, fresh water tank, deck and superstructure. Deep cracks were repaired in the lower part of the side spuds, and the bow leg had part of its lower, heavily worn structure replaced. A time-consuming task was to dismantle and reinstall more than 60 fenders to enable maintenance works to be carried out on the hull where they were installed.

An important task on the Spirit was to inspect all four propulsion thrusters (including the two retractable azimuth thrusters). The Bioblock (sewage treatment plant) was also replaced with a new one. Numerous steel and piping works, as well as maintenance and painting works were carried out on the hull, including painting of fresh water tanks and other areas of the ship, such as tweendeck, crane, inner part of the bulwark, railings, etc. Electrical and access works were also carried out in relation to the modification of the DP2 system.

Most of the ship’s areas, including tanks and rooms, were renewed, and a new access to the engine room was provided. A lot of steel work was also done on the open deck and the hull (including new fendering).

Atlantic Star set a record!

In August, the Atlantic Star Con-Ro ship, owned by the Grimaldi Group and operated by ACL, entered Remontowa. The Atlantic Star is the longest and the heaviest ship ever lifted in the largest floating dock in Remontowa. The overall length of the ship is 296m, width 37.6m and weight is 37,170 tonnes (without ballast). The challenge was to dock this ship, which required six months of detailed preparation. The dockmasters, supported by the knowledge of the shipyard’s general designer, developed a precise procedure for the safe drydocking. The ship underwent a standard dock and maintenance repair, including works on the steering system, replacement of sections of outboard pipelines, maintenance and painting work, overhauls of bottom-board fittings, as well as the scope of steel replacements.

Scrubber/BWTS retrofits

Remontowa has continued to retrofit the Grande Marocco series of ships owned by Grimaldi Group with EGCSs. The first ship to leave the yard in March with a scrubber installed was Grande Gabon. She also underwent a large range of works that included the stern ramp, which was dismantled for extensive repairs. She was followed by the Grande Marocco, Grande Sierra Leone, Grande Congo and Grande Guinea, which underwent a scope of works. Prior to the scrubber installation, the shipyard adapted an appropriate room in the cargo space and equipped it with the necessary systems, such as ventilation, fire-fighting systems, etc. In the second quarter, the last three ships arrived at Remontowa, with the Grande Guinea being the last to enter the manoeuvring basin, meeting up with the Grande Congo, on which the repair works were almost completed.

Busy at SMS Group

The SMS Group has enjoyed a busy first quarter to its financial year; completing several major programs of interior outfit and numerous traditional engineering-led refits.

The interior outfit projects team have been focusing on the pride of the Royal Navy; HMS Queen Elizabeth and HMS Prince of Wales. Works include, but aren’t limited to, the major refurbishment of Flag Officers cabins and dining room. The team also made significant improvements to the wardroom and mess areas onboard HMS Prince of Wales.

Engineering-led refits include major works onboard one of Condor Ferries conventional ships alongside in Poole, numerous support roles within BAE Systems in Portsmouth, and Babcock International in Plymouth. The business also undertook refit works in Lowestoft on behalf of Trinity House, UK Border Force, Svitzer, Woods River Cruises and numerus WFSV / CTV operators which supports the energy sector at the bottom of the North Sea. From Dover the business has supported numerous cruise operators seeking Covid-related short layovers and several dive surveys. The Avonmouth business has supported major refit works for Cemex, whilst the team in Southampton completed numerous minor projects within the Port and moved to new and improved premises.

Major Calmac ferry upgrade

The UK’s largest ferry operator – CalMac Ferries Ltd – has awarded a UK based marine power and electrical engineering business a three-year framework contract for the provision of electrical installations services.

Located in the North East of England, MJR Power and Automation has been appointed – alongside three other companies – to deliver its leading marine services to support CalMac Ferries with a series of upgrade projects planned over the next few years.

Forming part of CalMac’s resilience program, this will see the ferry operator undertake major upgrades to modernise 33 of its ferries – currently operating 29 routes across the west coast of Scotland – including upgrading of main power, electrical and automation system infrastructure across the fleet.

The framework award comes on the back of MJR Power and Automation successfully delivering a series of contracts which has seen the business carry out major electrical power and control upgrades and installations over the past 18 months during planned scheduled maintenance at shipyards across Scotland and the North of England.

Speaking about the framework award, Paul Cairns, Managing Director at MJR Power and Automation said: “We are delighted to have been selected as CalMac’s partner of choice for marine electrical upgrades and installations through a very competitive and rigorous tender process. The successful delivery and execution of recent major infrastructure projects demonstrates CalMac’s confidence in our business to provide safe, efficient and right first-time solutions, subsequently leading to us being awarded the framework agreement.

“We have an unrivalled level of repeat business reinforcing our reputation built on 25 years of experience and technical expertise of marine systems and applications. This is all underpinned on a firm understanding of both the customers and marine classification society requirements, coupled with the quality and management of works carried out by our first-class engineering and installation teams.

“We pride ourselves on working as an extension to our customers’ teams to deliver the very best results and we have forged a great relationship with CalMac over the last 18 months, built on quality and trust.”

Major upgrades successfully completed by MJR Power and Automation include the propulsion and pitch control system with over 12000 metres of cable supplied, installed and tested as part of the delivery of electrical, control and data infrastructure upgrade completed on four ferries including one of its flagship vessels, the MV Clansman Isle of Lewis.

The company also installed over 5000 metres of marine Cat6 cable for the new state of the art marine approved CCTV system which included the design, specification, installation and commissioning covering three ferries consisting of the largest vessels in the fleet, the Caledonian Isles.

Operating for over 25 years in the marine, offshore & energy sectors, MJR Power and Automation is a leading specialist in marine power, electrical and automation engineering, and provides complete end to end complex projects from design, engineering and construction to installation, commission and worldwide service from its headquarters in Teesside. The business has completed a number of high profiles, turnkey projects for global leading brands. Its impressive client portfolio includes the likes of Stena Line, P&O Ferries, Condor Ferries, Subsea 7, Van Oord TechnipFMC, and DeepOcean, to name a few.