While the consequences of Covid-19 remain open-ended the pandemic is concluding the case for condition-based information, as owners and operators realise the benefits of original equipment manufacturer support in the digital age.

Whilst condition-based information backed by responsive specialist support and technical expertise have become increasingly key to effective maintenance planning and maximising operational availability, Coronavirus related restrictions have consolidated the appeal.

“In the past, the service organisation footprint and logistics management capabilities required to effectively support ships in operation and maintaining a schedule have perhaps not been fully recognised,” says John Carnall, MacGregor’s Senior Vice President, Global Services. “With the current limitations on travel and provision of onboard support, this has changed and customers are seeing the value of locally based specialists and remote technical expertise in ensuring that the right parts are available in the right place at the right time.”

With 850 specialists and 60 service centres located in 31 countries worldwide, including recent expansion to provide enhanced support to customers operating in the Americas, MacGregor fully understands the value of local specialists supported by ‘centre of excellence’ based technical experts, and an ability to supply original spare parts from regional warehouse stock.

“Customers are recognising the value of condition-based information as a maintenance planning advantage,” adds Dennis Mol, Vice President, Digital and Business Transformation. “It provides peace of mind with respect to mission-critical systems and operational continuity, and is something we expect will be increasingly required by shipowners and operators to maximise the efficiency and value of expensive assets”.

Condition based maintenance management

“As an industry, we are moving towards predictive tools, which will help to eliminate unplanned downtime, ultimately reduce maintenance costs and increase revenue and profitability,” adds Mol.

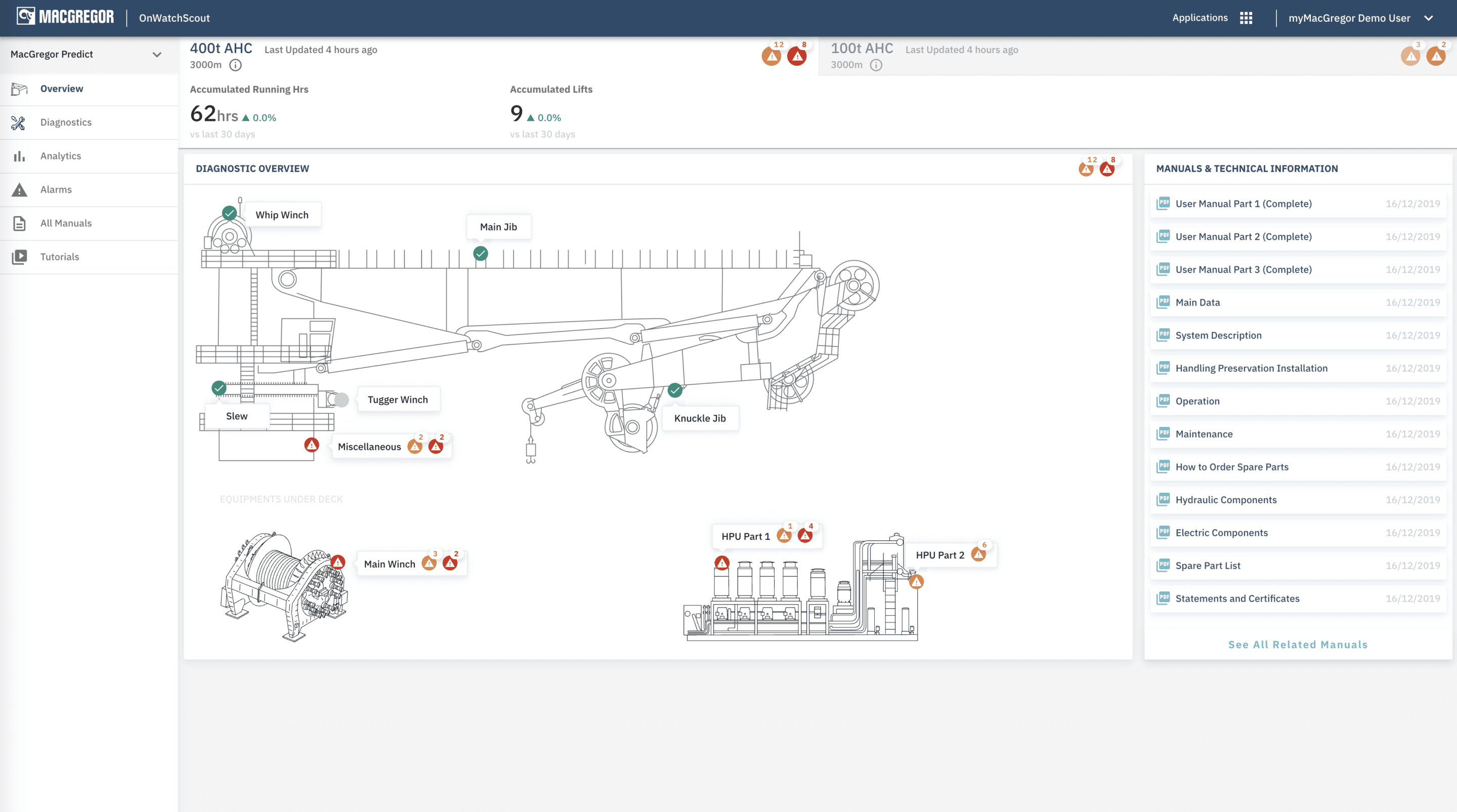

He says MacGregor’s extensive knowledge is being channelled into developing algorithms that can predict when certain equipment requires maintenance based on use and condition, rather than relying on conventional time-based service schedules. Digital advances in this arena include ‘OnWatch Scout’, with two merchant and offshore pilots currently in operation and more awaiting installation.

“High quality, accurate, predictive maintenance is possibly one of the most important elements of service provision,” says Mol. “OnWatch Scout is a predictive tool developed to ensure that equipment is able to operate more or less continuously. It detects variations in the behaviour of components and predicts if something might happen. We then have the ability to notify the customer and advise them of the preventative steps that need to be taken to avoid component failure.

“The crew and operation centres engaged in the pilot programmes are very happy with the ease of system use and information being made available, which is providing common visibility of the crane operating information. This, in turn, is supporting effective ship to shore communication and coordinated decision making.”

Future development plans include extension of the OnWatch Scout capability beyond cargo and load handling cranes to include hatch covers, deck machinery and other critical equipment and systems.

Making expert knowledge available to customers through simulation-based training is another information-based capability that enhances crew capabilities, operational safety and equipment reliability.

“Whereas OnWatch Scout provides real-time, condition based information, ‘digital twin’ services provide a dynamic environment that enable procedure demonstrations and training to take place, with the ability for this type of training to be undertaken by crew onboard being a planned development of MacGregor’s,” says Mol.

Close is good, even closer is better

Good maintenance practices positively support business operations, but John Carnall emphasises that saving costs does not mean cutting down on maintenance itself: “It means being focused on doing it the right way,” he says.

“OEMs know their equipment better than anyone else. This enables us to more easily assess and determine its condition, ensure that parts are not replaced unnecessarily, and develop tailored, cost-effective plans for repair and renewal. Technical personnel can also make relatively small adjustments to operational parameters that deliver material performance benefits.”

This is particularly important with reported shipping incidents on the rise and an increased level of scrutiny applied to equipment failure-related insurance claims, particularly where genuine parts have not been used or maintenance not carried out.

“In many cases, these incidents could have been avoided through periodic visual inspection, but the prolonged industry downturn and current Coronavirus crisis has meant that maintenance budgets have been impacted,” Carnall notes.

“All equipment, if left unchecked, will gradually deteriorate in performance and efficiency, and ultimately fail. Shipowners and operators know this and that planned maintenance is more cost-effective because emergency repairs are almost always more expensive. Whilst it is understandable that longer term cost benefits may not be the highest priority when short-term survival is in question, ongoing operational reliability and potential reputational damage must also be considered.

“When we are able to have an effective dialogue with customers, jointly plan required work and then carry it out as agreed, we are the best at what we do,” Carnell says. “With this being increasingly combined with the availability of condition-based information to support effective maintenance planning, we can further enhance the world-class operational support expected of MacGregor, even in the most challenging of times.”