Interview with Alvin Gan of Seatrium

Seatrium is a trusted partner in the offshore and marine industry

Seatrium Limited is a Singaporean state-owned company formed in 2023 from the acquisition of Keppel Offshore & Marine by Sembcorp Marine which was subsequently renamed Seatrium.

Alvin Gan leads the Repairs and Upgrades business, overseeing a broad portfolio of services that includes the repair, refurbishment, retrofitting, life extension and upgrading of vessels, offshore platforms and marine structures. His role also extends to EPC solutions for upgrades and conversions, e.g. FSRUs and FPSOs, with a focus on green technologies, energy efficiency, alternative fuels and low-carbon retrofitting solutions.

Gan joined the group in 1995 and held various roles in the ship repairs and upgrades business, with extensive experience in both operations and project management. He plays a key role in forging long-term partnerships with customers in delivering innovative, high-quality solutions to meet the evolving needs of the marine and offshore industry.

He holds a Bachelor of Engineering (Hons) in Naval Architecture and Offshore Engineering from the University of Strathclyde, UK.

Alvin Gan

Q. What was the key rationale for the combination of Sembcorp Marine and Keppel Offshore & Marine and has the merger met all expectations?

A. The business transformation of both companies created Seatrium, a premier global player offering offshore renewables, new energy, and cleaner solutions in the offshore & marine sector. The enlarged company will benefit from synergies from combined competencies and capabilities, as well as enhanced competitiveness through greater scale and cost efficiencies.

Q.How has the combination affected the ship repairs and upgrades business of the group?

A. As a group, we are now operating on a bigger global scale, allowing us to offer our customers with end-to-end solutions in repairs and upgrades all through one Seatrium. With 14 yards globally and 20 drydocks, we will offer greater footprint, capacity and capability to our customers internationally.

Our customers can also leverage our deep engineering and project management expertise across the group; we offer a full suite of products and solutions in ship repair and upgrades.

As a key business pillar under the group, Seatrium’s Repairs and Upgrades business continues to be the world leader in LNG and FSRU repairs and conversions. We are now focusing on turnkey EPC retrofit solutions in maritime decarbonisation, pioneering the world’s first green ammonia-capable dual-fuelled vessel, FFI Green Pioneer, and partnering with the Maritime & Port Authority of Singapore (MPA) to pilot hydrogen fuel cell conversions for the nation’s first fuel cell retrofit on the Penguin Tenacity, a roll-on/roll-off vessel.

Recently, the group also completed the world’s first two full turnkey Onboard Carbon Capture and Storage (OCCS) retrofits on Solvang’s Clipper Eris and MOL’s Nexus Victoria.

Q. What about the oil & gas conversions part of the business?We have been actively growing our business in Oil & Gas Newbuilds and Conversions?

A.In 2024, we secured several contracts including the FPU Sparta for Shell, FPU Kaskida for bp, and various FPSO newbuild and topsides integration projects for Petrobras, MODEC and SBM Offshore respectively. Last month, we signed an MOU with bp for a second FPU for deployment in the US Gulf of America [Gulf of Mexico]. These developments reflect the continued demand for such production solutions and reinforce Seatrium’s leadership position in this area.

To date, Seatrium has delivered the world’s first two FLNG conversions: the Golar Hilli in 2017 and the Golar Gimi in 2023.

We pioneered turnkey FSRU/FSU conversions, a growing business segment in which we have completed over 20 conversions since 2007.

Q.Do the yards still run as individual entities, or do they share work/projects across Seatrium?

A.Today, our yards globally are horizontally integrated under the One Seatrium Global Delivery Model, allowing us to scale the business.

All projects are organised under our Central Planning team, rather than at each of our yards, providing more flexibility in project management and forward planning. This unique end-to-end model centralises our global expertise onto a single operating platform, ensuring consistent and efficient delivery of solutions to our customers. To enhance operational excellence, our yards are supported by engineering and technology centres of excellence internationally.

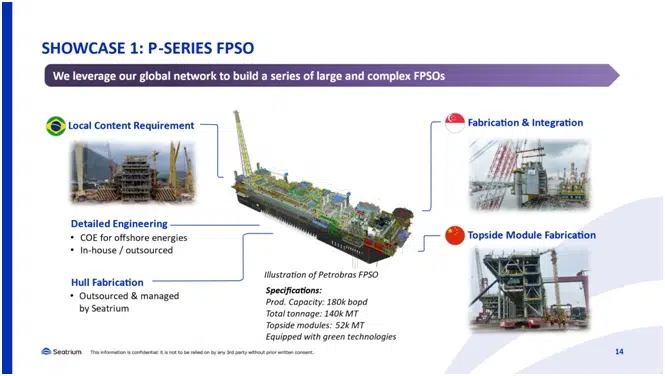

A good example is our P-series projects: We outsource the hull to partner yards, while topside modules are fabricated by our yards in Brazil, China and Singapore and will undergo integration in Singapore.

Q.Do you have any plans to expand the ship repair and conversion part of the business?

A. Our repairs and upgrades business continues to be a key pillar to our group, delivering on our commitments to our partners and customers. According to our earnings announcement, the repairs and upgrades segment delivered a revenue of S$1.1Bn in FY2024, up 7% from a year ago. This is driven by higher revenue per vessel as compared with FY2023, despite fewer vessels worked on.

In 2024, we signed and renewed several exclusive favoured customer contracts, bringing our total to 22 today. These contracts allow us to assist our partners with forward drydock planning of their fleet and enable capacity planning, which in turn results in revenue visibility.

We are also optimistic that periodic drydock maintenance, fleet rejuvenation and maritime decarbonisation will continue to drive demand in this part of our business.

Q. Do you have any plans for major changes to the yards?

A. To continue to scale the business through our One-Seatrium Delivery Model to enhance the operational capability of our yards globally.

We are investing in digitalisation to improve our systems and product services. As part of our Smart Yard initiative, we are leveraging smart video analytics, AI and digital twin technology augmented with real-time IoT (Internet of Things) to further improve productivity and operational efficiency.

Q. How do you see the future for ship repair in the region?

A. Singapore, with its strategic geographic location at the centre of the global shipping lanes, will continue to be pivotal in ship repair and Seatrium, with our proven track records and full suite of services, will play a leading role in this segment.

Driven by maritime decarbonisation, we see a robust global market with growing shipping demand across segments. More than 60% of the identified world fleet (tankers, LNGCs, containerships and cruiseships) is more than 10 years old, which means they will require more maintenance/upgrade work besides the mandatory drydocking work. We are in a good position to secure higher-value vessel upgrades and turnkey/energy efficiency retrofits based on our strong track record.

Seatrium’s track record in various repairs and upgrades segments includes:

- World leader in LNGC repairs & conversions – 989 projects delivered since 1979

- Pioneer in FSRU/FSU conversions – 21 delivered since 2007

- Asia’s leader in cruise repairs – 411 projects delivered since 1978

- Regional navy MRO strategic partner – 438 vessels repaired since 1977

- 22 alliances & long-term Strategic Partners.

Q. Is there anything you would like to add?

A. Seatrium has a long history and proven track record as a trusted partner in the offshore and marine industry. We are committed to building deep and mutually-beneficial partnerships with our customers to deliver the best Seatrium experience through the highest standards of safety, reliability, and quality in the journey towards decarbonisation and sustainable shipping.

More articles like this can be found in the latest issue of DryDock magazine