By ACO Marine Managing Director Mark Beavis

The wastewater treatment plant is, sadly, rarely at the forefront of naval architects’ minds when designing a vessel, yet it is one of most crucial components onboard ship.

Without an effective wastewater management solution capable of meeting increasingly stringent environmental regulations, effluent discharge levels outside the mandatory limits can result in vessels being delayed at port, at the very least. But it is not necessarily a case of bigger is better. With onboard space at premium, smaller bespoke systems can now be designed as easy-install flat-pack solutions without impacting treatment efficiency or flow rates.

When V.Ships Offshore approached us to find a wastewater management solution for the 8234t Dive Support Vessel (DSV) Bibby Polaris, we did find ourselves thinking long and hard as to how best we could fit a Clarimar MF-10 treatment unit into the space available. It was akin to the proverbial “quart into a pint pot” scenario.

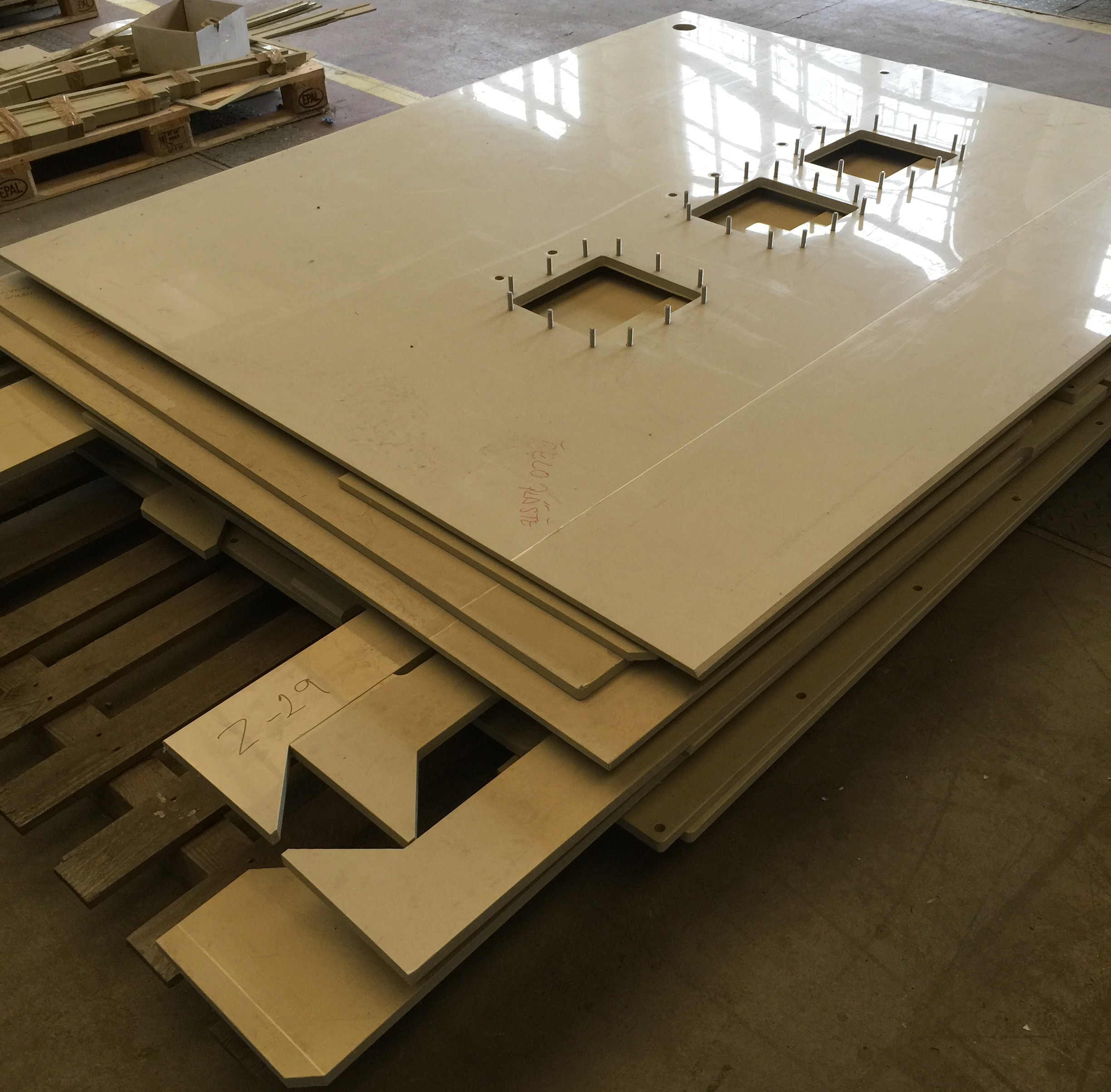

Replacing the vessel’s wastewater management system with one capable of meeting new MEPC 227(64) requirements was certainly a challenge, but we took a more radical approach to retrofit installation and developed the Clarimar MF for supply and install as a flat-pack.

As far as I’m aware, it is one of the first large pieces of engine room machinery to have been supplied to a ship as an ‘on-board build’ and we believe this could be the way forward for all sorts of machinery space equipment.

Where space is limited, we now have a solution where we can feed the Clarimar MF wastewater treatment unit in ‘sheet-by-sheet’ to the assembly/installation site for final welding in-situ.

In the case of the Bibby Polaris project, by rotating the unit through 180 degrees, we were able to minimise the removal/relocation of existing equipment so that all yard and shipboard staff had to do was simply remove of the old STP.

We were also able to utilise its existing black water vacuum collection station, but we provided a dedicated control panel mounted on the Clarimar MF-10R unit to facilitate control and operation, with the Clarimar MF providing master control in a master/slave arrangement for the complete wastewater management solution.

Although Clarimar MF maintenance is negligible and no chemicals are required for the treatment process, marine engineers still need to have access to the unit, of course. To this end, we mounted the base plate directly to the tank tops, with the Clarimar base below the deck plates – just enough so that the tank access cover to the STP tank openings remained accessible from above the plates.

The components and quality of the build-onboard units are exactly the same as the Clarimar MF units we put together at our production facilities in the Czech Republic. They are manufactured from high performance material which, unlike coated black steel, is completely corrosion resistant and lightweight. And once installed and commissioned the Clarimar MF can simply be left to run.

Delivering machinery flat-packed, ready for construction and welding in-situ saves a considerable amount of time during the planning and installation stages. We are also able to keep costs down to a minimum as there is no need to cut large holes into the vessel’s structure and patch them up again.

We believe it will even be possible to supply, install and commission systems while the vessel is still operational, although this will be dependent on a number of factors and will have to be considered on a project-by-project basis.

Picture below: the flat-packed Clarimar