FPSO tank inspection with a drone

Inspecting FPSO tanks with a drone not only reduces the time required but also virtually eliminates the safety risk.

Floating production, storage, and offloading (FPSO) vessels offer effective and flexible infrastructures for offshore oil production operations. These huge ships can process and store oil until it can be transported by tanker or pipeline. They are easy to install and can be relocated as required to optimise a production portfolio.

FPSOs have a high development cost, but a long lifespan because they can be relocated as required and used well beyond the life of a single production facility if maintained.

Typically, the processing equipment is located above the vessel’s deck, while oil storage is located below the deck in the double hull.

These vessels hold a crew of between 50-70 people. For safety and environmental reasons, the vessels must be inspected and certified every few years.

Floating production, storage, and offloading (FPSO) vessels offer effective and flexible infrastructures for offshore oil production operations

Customer needs

Inspection experts TEXO were asked to perform an inspection on the oil tanks in an FPSO.

A vessel in drydock can be inspected relatively easily by setting up scaffolding and utilising a large team of inspectors, but inspecting an FPSO on station is much more difficult and time consuming. Oil tanks cannot be emptied all at the same time for efficient inspection, both because the vessel must be balanced for safety and for continuity of operations. Generally, operators make two tanks available at a time – simply preparing the tanks for inspection can take weeks. Tank inspections traditionally require four to five rope access technicians, who may be left waiting for several weeks to be deployed while the tanks are prepared.

When the tanks are available for inspection, rope access work is dangerous and time consuming, with the inspection of two tanks taking significantly longer than drone inspection. In some cases, scaffolding may be required, which introduces new risks. In addition to the danger to the staff working at height, scaffolding can cause damage to tank coatings and dropped objects can contribute additional risk to the tank and the personnel.

While the labour is expensive, TEXO points out that the production slowdown while the tanks are unavailable is even more costly. Inspection is a certification requirement and promotes preventative maintenance: workers look for distortion, defects, buckling, and cracks, especially in toe wells and other high stress areas. Any problems found must be addressed during the process, adding more downtime if the defect is found late in the inspection process.

Solution

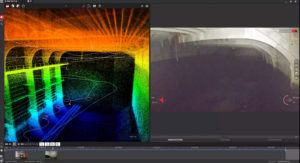

TEXO utilised the Elios 3 drone to perform the oil tank inspection in one week after the emptying and cleaning process, with a team of only two people. With the pilot located safely outside the tank, TEXO says that there is virtually no risk to the personnel, with the team performing four flights to map the tank, then creating a 3D point cloud of the asset.

The Elios 3 drone

The Elios 3 drone controller

The Elios solution represents a very significant savings in cost – but also offers better, more reliable data for repair and maintenance.

“Elios is such a good tool that it really just requires two people, versus five people for many days,” says TEXO’s Xiang Wong. “But also, it gives the surveyors on shore a lot of confidence that the entire tank has been inspected. Utilising the flight trajectory ensures teams have not missed any of the highly repetitive structure.”

Using rope access teams, says Wong, “You have to put your entire faith in the team that is working for you, because all of the pictures look the same. With the Elios 3 you can track where you have been – you have the video continuity. That’s a major benefit. A single set of data can be reinvestigated by multiple inspectors all with their own experience adding layer upon layer of expertise to it.”

The Elios 3 solution also allows the TEXO team to become more efficient in maintenance, to minimise downtime and the related costs. “With drones, you can inspect critical points, hot spots, or stress concentration areas first, and identify any problems right away,” explains Wong. “When you have identified a defect early on, you can work with the naval architects and surveyors to develop a solution while the tanks are still empty.”

The steam heating coils found on the bottom or sides of the tank offer a particularly good case in point. Heating elements form a dangerous environment and are fragile and easily breakable. Human inspectors are not always able to identify the exact source of a problem: flying a complex pattern with the collision-proof Elios solution and creating a point cloud representation of the system allows engineers to identify a problem more easily. Point cloud data can be merged with topside data to form a complete picture of the tank, helping engineers to identify the correct placing of any cut into the tank for repair.

A screenshot of the inside of the tank

Results

TEXO was able to provide its client with an accurate inspection, including point cloud data that was previously unavailable. The inspection was performed in only four days, compared to a usual timeframe of up to two weeks, and the client feedback was positive. The client is now interested in pursuing further use of the Elios solution for FPSO inspections.

The Elios inspection provided the inspection with no risk to personnel, and was able to offer onshore surveyors complete confidence that the entire area had been reviewed.

A live map on the tablet

Conclusion

TEXO sees significant value in using the collision-proof Elios solution for a variety of oil and gas inspection projects. The TEXO team has used both Elios 2 and Elios 3. While Elios 2 offers many benefits over traditional rope access inspection, TEXO cites the advantages of location referencing and point clouds using Elios 3. “If there are no problems in an inspection, the Elios 2 is great,” says Wong. “But for fixing issues, the Elios 3 is needed.” In future, TEXO is looking forward to exploring further use cases, like semi-submersible vessels. “Semi-submersibles are almost like a maze to navigate,” explains Wong. “The Elios 3 is the perfect tool for that. Elios really negates the need to put men in confined spaces.”

An image showing what the inspector sees

TEXO Group is certified by DNV (Det Norske Veritas) as a service supplier approved for surveying using remote inspection techniques (UAV) as an alternative means for a close-up survey of the structure of ships and mobile offshore units.

More articles like this can be found in the latest issue of Protective Coatings Expert magazine