The technology group Wärtsilä has been contracted to upgrade the performance of four vessels owned by Kuwait Oil Tanker Company (KOTC), a subsidiary of Kuwait Petroleum Company (KPC), by retrofitting Wärtsilä Fuel Efficiency Boost solution to the ships’ main engines. The modification will reduce fuel consumption, and correspondingly lessen the environmental impact by lowering greenhouse gas emission levels. The order with Wärtsilä was placed in the first quarter of 2020. KOTC and other major ship owners who have taken a proactive approach towards environmental protection have been actively looking for ways to reduce their fuel consumption and carbon footprint, thus paving the way for them to reduce greenhouse gas emissions. As a result, the Wärtsilä Fuel Efficiency Boost initiative has attracted considerable interest, and similar orders from other large shipping companies have been placed in recent months.

The Wärtsilä solution is based on two-stroke engine optimisation technology for selected Wärtsilä RT-flex and earlier deliveries of X-type two-stroke engines. The four KOTC very large crude carriers (VLCCs) to be retrofitted operate with 7-cylinder Wärtsilä RT-flex82T two-stroke main engines. The retrofitting of the vessels with the Wärtsilä Fuel Efficiency Boost will take place over the coming six months.

“Our smart marine approach is dedicated towards raising efficiencies and improving the environmental sustainability of marine operations. The Wärtsilä Fuel Efficiency Boost is completely aligned with this philosophy, while at the same time lowering operating costs,” says Riad Belaid, Area Sales GM, Middle East & Asia, 2-stroke & Specialised Services, Wärtsilä Marine Business.

“By modifying the main engines of these carriers, we are assured of operating with the latest technology and having the best operational efficiency. We know and trust Wärtsilä’s high quality products and systems, and we appreciate the excellent support they offer,” says KOTC’s Acting CEO, Ali Shehab.

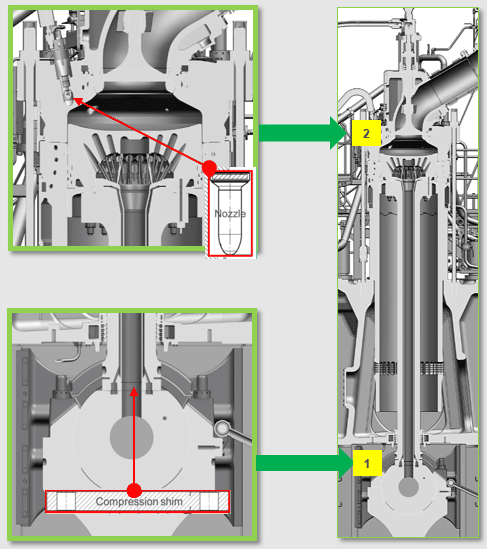

The Wärtsilä Fuel Efficiency Boost is a well-balanced combination of an increased compression ratio and modified injector nozzles. Together with optimised engine tuning parameters, it allows fuel savings of up to 4%. The pilot installation showed around 10~12 tons per day lower fuel consumption than a sister vessel operating the same route, and resulted in 1195 tons of fuel savings over the 9 months pilot period.

The Wärtsilä Fuel Efficiency Boost is based on 2-stroke engine optimisation technology and offers fuel savings of up to 4 percent, resulting in lower greenhouse gas emission levels.

In 2019, Wärtsilä successfully installed the company’s Intelligent Combustion Control and Fuel Activated Sacless Technology (FAST) upgrades on these same four vessels.