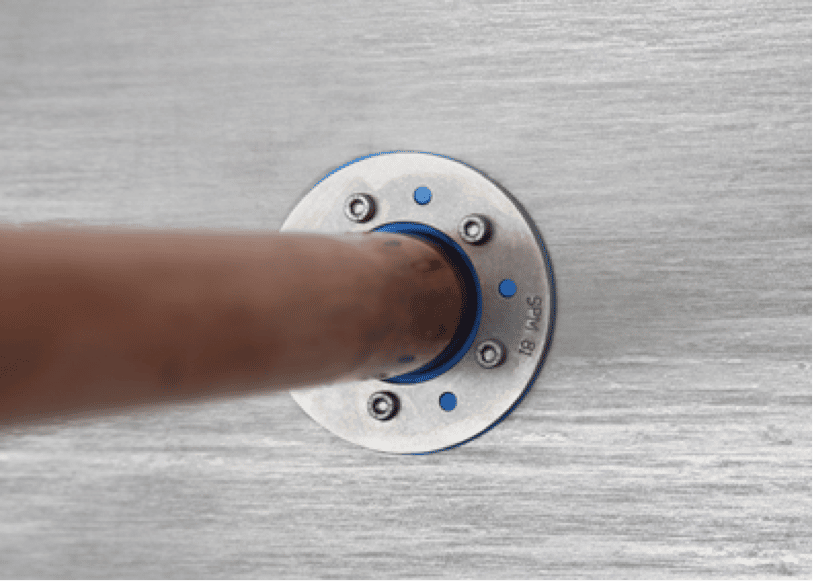

Further scope has been added to the Roxtec SPM seal. The non-weld metal pipe sealing solution is now certified for use in aluminum structures.

The Roxtec SPM seal has received a warm welcome from shipyards, designers and engineers as it ensures safety and operational reliability, without any downtime or cost normally associated with welding. It seals and protects to A-Class standards, steel, stainless steel and copper pipe penetrations against fire, gas and water onboard marine vessels and offshore platforms.

Thanks to the new type approval certificate in respect of aluminum structures, it will not only be used in steel decks and bulkheads on large vessels and platforms, but also in yachts, catamarans, high speed ferries, fast patrol vessels and other light-weight aluminum vessels and structures.

With the ability to protect metal pipe sizes up to 222 mm in A-60 fire rated zones and provide further protection against water (1 bar) and gas (0.67 bar), typical application areas where these non-welding benefits will be utilized include lines for chilled and potable water, fire suppression systems and hydraulic fluid and lubrication lines.

Practical protection

The Roxtec SPM seal is beneficial for shipyards who want to avoid the complex and expensive welding process and ensure certified protection where welding is either not allowed, recommended or desired.

The solution also delivers several other advantages, such as enabling users to pass the pipe material of their choice through any metal or aluminum structure without the need to change or interrupt the piping system when trying to overcome the risk of galvanic corrosion.

The Roxtec SPM seal provides installation flexibility. It is installed from only one side of the deck or bulkhead which can vary in thickness from 5 to 15 mm. Due to the in-built tolerance of the solution, it also maintains a tight seal around the pipe even when installed inside any uneven or irregular opening.