MarineShaft shows worldwide rudder repair capability

MarineShaft recently showed off its talent by completing a successful on-site service job in Iceland and a comprehensive case involving both in-house rudder repair and manufacturing of rudder components, combined with on-site technical supervision at a shipyard in Canada.

The job in Iceland was completed over the course of three days when two of MarineShaft’s service engineers carried out precision alignment and machining tasks on a vessel’s rudder system.

The rudder line was misaligned, so MarineShaft’s team machined the rudder heel housing on-site to restore proper alignment, remove corrosion and correct the deviation. After realignment and precision machining, a new bush could be mounted securely in a clean seat, ensuring long-term performance and reliability.

The work scope of the rudder repair Included:

- Mounting of laser alignment equipment

- Measuring the rudder line from steering gear to rudder heel

- Machining rudder heel housing to correct misalignment

- Re-measuring the rudder line after machining

- Machining the rudder flap bushing seat for proper fitting of new bushing.

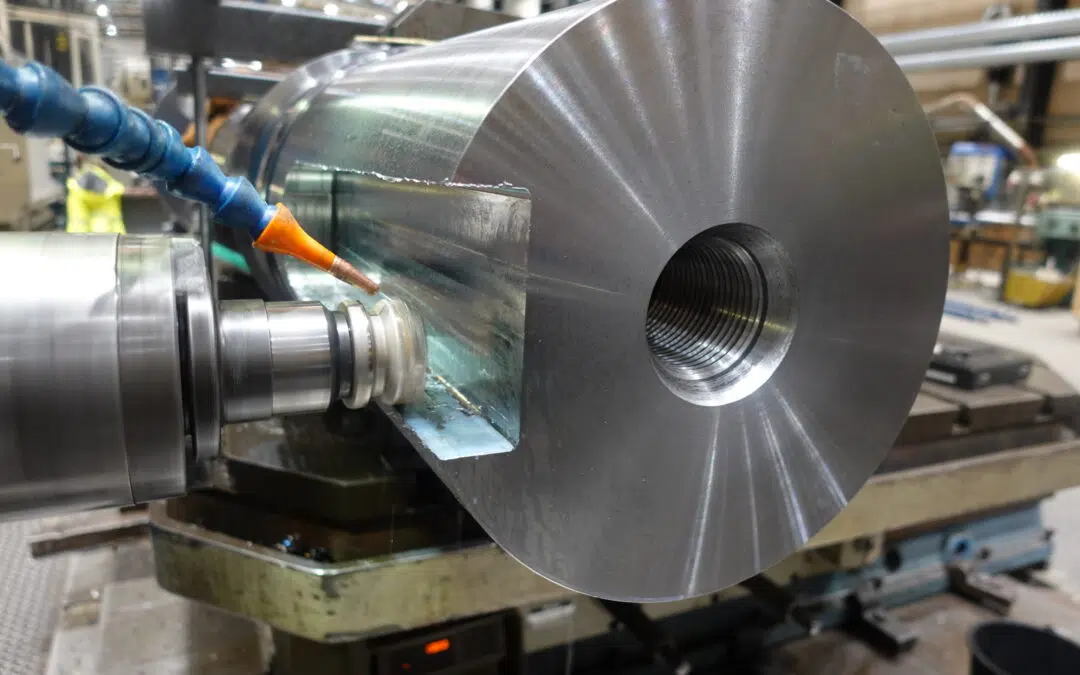

Getting ready for laser alignment of rudder line in Iceland –

Rudder repair from workshop to shipyard in Canada

MarineShaft also recently completed a comprehensive case involving both in-house repair and manufacturing of rudder components, combined with on-site technical supervision at a shipyard in Canada. While many are familiar with MarineShaft’s extensive workshop capabilities, fewer know that the company also offers expert on-site supervision and alignment services worldwide.

Providing full-scope rudder repair solutions – from initial inspection to final installation and blue-fitting – remains a core focus at MarineShaft. The company continues to invest in advanced mobile equipment to support these services efficiently across the globe.

A 191m-long bulk carrier suffered serious rudder damage after a grounding incident, requiring both repair and replacement of rudder components.

MarineShaft was tasked with measuring several existing rudder parts to prepare a quotation for manufacturing a new rudder and steering gear components, as well as repairing the damaged rudder tiller. With raw materials already in stock, the company was able to offer a short delivery time for the required components.

Manufactured components included:

- One new rudder stock with shrink-fitted stainless-steel sleeve Ø1,260/500 x 4,325mm

- One new ram pin and ram

- One key carrier

- Coupling bolts and nuts.

The damaged rudder tiller was shipped to MarineShaft’s workshop for full repair and precision blue-fitting with the new rudder stock. Upon arrival, the tiller – which had suffered deflection – was NDT tested, hot straightened and subsequently welded on the fork surfaces. Post-weld heat treatment was carried out, followed by a second round of NDT to verify structural integrity.

Coupling bolts and nuts were produced in oversize dimensions and delivered ready for final fitting on site.

MarineShaft rudder repair supervision

At the request of the client, a senior MarineShaft service engineer travelled to Canada to supervise and assist with the installation of the rudder system, including the steering gear. The rudder blade had been previously removed for line boring and machining to adapt it to the new bolt dimensions and a new seal box delivered by the OEM. Final tiller alignment was completed by the equipment manufacturer.

Thanks to precise coordination and efficient execution, the full installation of the rudder equipment was completed within just eight days.

These operations highlights MarineShaft’s ability to mobilise quickly and perform high-precision work directly on site, wherever its clients need. The company’s specialised laser alignment equipment ensures accurate results when aligning rudder and shaftlines, contributing to reduced wear and improved vessel efficiency.

“We travel worldwide and bring the workshop to your vessel – reducing downtime and saving both time and costs,” says Hanne Magnussen, MarineShaft’s Marketing Manager.

A senior MarineShaft service engineer travelled to Canada to supervise and assist with the installation of the rudder system