Machine Learning has produced results at least equal to human judgement when inspecting coating condition, explains Gu Hai, ABS Director of Technology

Assessing the condition of marine and offshore coatings continues to be one of the major tasks to be addressed during class survey, and one that has benefitted from the increased use of remote inspection technologies (RITs). The development of more effective RITs – including unmanned and remotely operated vehicles – has enabled safer and more efficient visual inspections of the condition of protective coatings in historically hard to access and dangerous locations.

Visual inspections by properly trained and highly experienced surveyors continue to make up the majority of maintenance surveys, but the growing use of RITs provides an opportunity to augment human skills with computing power.

The accuracy of these assessments is commonly dependent upon the inspector’s previous experience, as well as their familiarity with the different types of structures being inspected. While class inspections demand a high level of experience from surveyors, these factors may cause inconsistency during coating inspections.

To overcome the challenges in conventional inspection of coating condition and advance the use of new technology, ABS is leading a project to apply Artificial Intelligence (AI) and Machine Learning (ML) in an image recognition tool designed to aid inspectors in reviewing data and making coating condition assessments.

Positive initial results

Phase one of this work was completed in 2019 and has been followed by a second phase to expand the scope of the data used to train the AI tool and was concluded in the second quarter of 2020. Where the pilot phase delivered a reasonably positive result using only a few hundred images, the need for improved accuracy saw the use of about 10,000 images for enhanced accuracy.

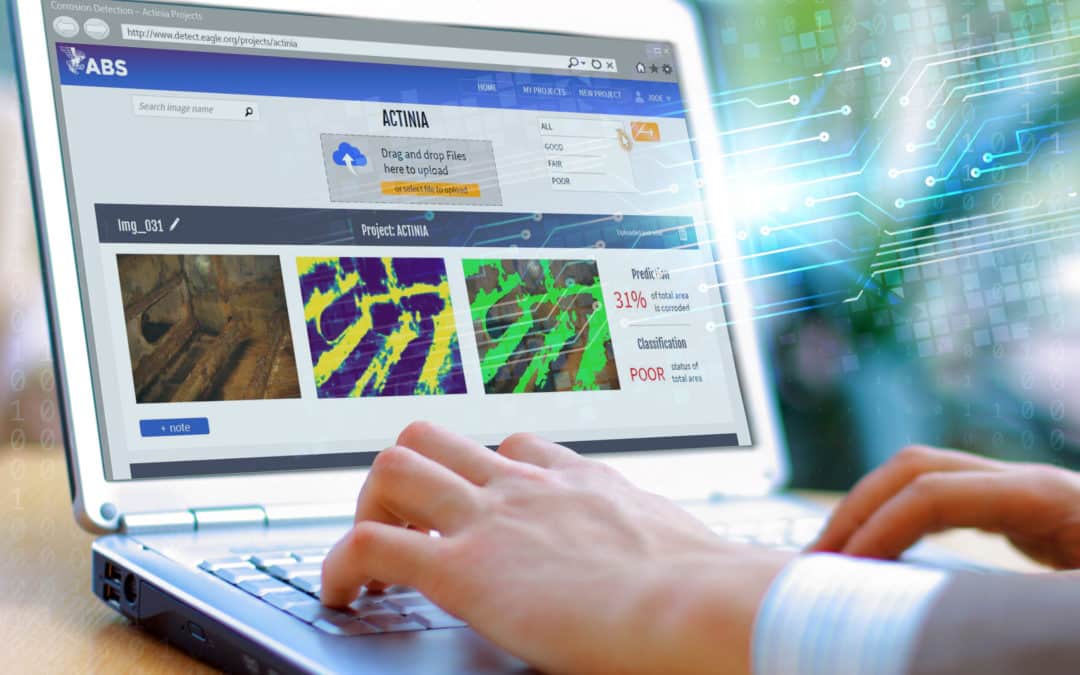

The ML-based image recognition tool developed by ABS can automatically analyse input data, identify coating failure areas and grade the coating condition of the structure. Inspectors can use these results as references, just like the assessment scales from coating guidance, to improve the consistency of coating assessment. The tool can also be utilised during screening inspection processes, where it can be used as a filter to identify the critical areas for review purposes.

The ML algorithm/model program utilises images taken from different types of maritime and offshore assets and it can deal with various kinds of structural components, coating failures, lighting conditions and rust.

To achieve the best possible results, the ABS study employed ML algorithms known as Convolutional Neural Networks (CNN), also used in autonomy and facial recognition in analysing images and videos.

Representative datasets

Besides model selection, another key action to help improve the performance of the CNN model was to prepare a large dataset with high quality data, which also need to be properly labelled by subject matter experts. The CNN models then used these data in the algorithm training process, applying the judgement of subject matter experts to learn based on the labelled patterns and features known as a Supervised Learning Approach.

The total database used in this study consists of approximately 32,000 images, taken from different types of marine and offshore structures, most of which are internal tank structures such as water ballast tanks, cargo tanks and oil tanks. As different models may need different formats of labels for training, different labelling processes must be employed.

To conduct the training process, first the model was trained and validated using the labelled training dataset, then was tested by the training dataset (also labelled, but differently from the training set) to judge the performance of the data. If the test results were unsatisfactory, either the model or the training data was improved until an acceptable performance of the model was achieved.

The project has proven the value of using AI technology in the marine and offshore industry as a means of supporting trained inspectors with a fast and reliable means to aid their decision-making processes during coating assessment tasks, especially when remote inspection technologies are applied.

A reliable reference

Through data tests and case studies, it has been concluded that the tool can provide reliable reference data and information to surveyors in the field. Test results of the best performing model show its ability to identify coating failures from field images that have not been previously processed.

These factors support the value of the tool to act as a scanning process for inspection with remote inspection technologies and as an electronic coating evaluation standard/guideline to aid inspectors.

These tools and capabilities will continue to improve. With the iterative labelling process integrated, new data will be fed continuously into the training process to improve the capability of the tool, make it more accurate, reliable and general.

While currently focused on coating assessment of internal tank structures, the scope of the AI tool can be expanded to coating assessment of other types of structures or evaluating of other defects such as cracks, fractures or large structural deformations.

Matching human judgement

A common question from ABS clients is whether the algorithm is of sufficient quality to accurately assess the problem of coating failure. Comparison studies show the tool can match the human judgment in general for the purpose it is developed for.

The AI tool will mark areas of corrosion with colour to give a rating of the coating’s condition based on which the client can make decisions. The accuracy of the AI algorithm for the grading task is above 90% for test data used at the development stage. Field test results have also shown similar accuracy level to human inspectors.

In addition to images with which to train the AI, the process needs labels placed by experienced surveyors to indicate to the computer the location of the corrosion. Improved labelling of the corrosion provided by the surveyors will lead to better accuracy of the AI output.

Work continues to make the tool more accurate for assessment of coatings and conversations with clients are ongoing to customise the tool for their particular applications using images specific to their assets and structures.

If you enjoyed this article, visit the PCE website, or sign up to receive your printed or digital issue of PCE Magazine for FREE