ABB has announced study results which show a 202% return on investment (ROI) from using ABB Preventive Maintenance. The new study indicates that the payback of preventive maintenance is immediate, while the Net Present Value – a measure of profitability of a projected investment – can be around US$1.3 million over three years for a typical organization.

Preventive maintenance involves maintaining and servicing equipment at regular intervals in line with manufacturer recommendations, rather than waiting to carry out reactive or corrective repairs – also known as ‘corrective maintenance’. According to the study, a corrective maintenance approach can have financial consequences for a company. The objective of preventive maintenance is to reduce the chance of equipment failing unexpectedly, by performing maintenance whilst it is still operational.

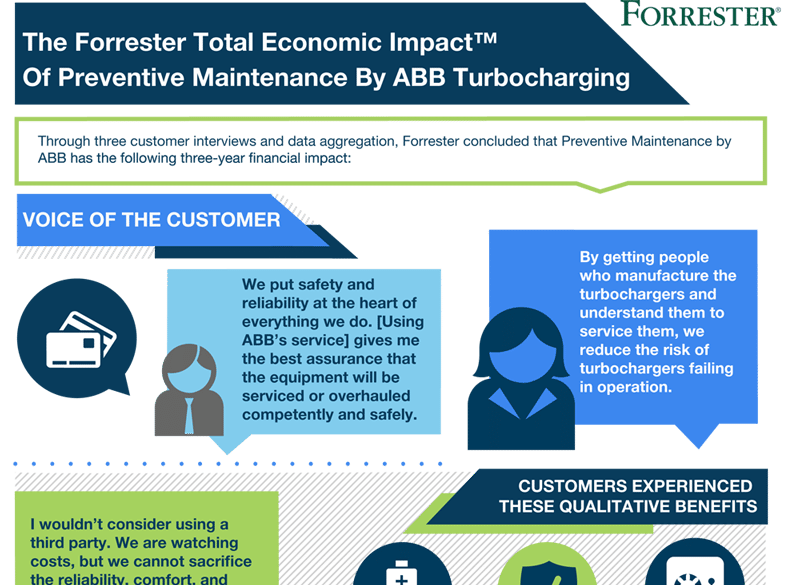

ABB commissioned Forrester Consulting to conduct a Total Economic Impact (TEI) study* to assess the ROI companies can achieve by using the Preventive Maintenance service model for their turbochargers. Forrester investigated three companies with many years of experience using ABB Turbocharging’s Preventive Maintenance, conducting interviews and gathering data from across the organizations.

Compiling these findings into results for a single ‘composite organization’, the study concludes that the cost savings from avoiding unplanned downtime over three years would amount to over US$780,000, while the avoidance of a catastrophic failure could save more than US$1.1 million over the same period. While less quantifiable, operational efficiency gains, and maintaining an organization’s brand and reputation represent further benefits.

Engineers who were interviewed for the report discussed how a single turbocharger failure may not halt a vessel’s operations, but it can compromise efficiency and cause delays. The Swedish Club’s Marine Engine Damage Study in 2012 further reported how turbocharger damage could penalize ships’ owners earning power as it is “the most common and expensive damage category across all engine types”. Not servicing turbochargers at all, or using non-OEM parts, could lead to a serious failure that might leave a ship immobile. This would require expensive parts, costly rescues and potentially months of lost operations.

Customers interviewed were adamant that ABB’s Preventive Maintenance approach had improved the safety and efficiency of their operations and helped avoid the risk of serious incidents at sea.

Rolf Bosma, Head of Service Sales, ABB Turbocharging, says: “Preventive maintenance is vital for sustained turbocharger performance, but also to ensure operational reliability and safety. To meet and exceed our customers’ expectations we are now developing our offering further, towards solutions that will increasingly prevent equipment failure, customized for different segment needs. In addition, operating in such a rapidly evolving market environment, it remains important for us to keep looking ahead, so we are also exploring exposure-based and predictive maintenance offerings, for their potential to further enhance our customers operations.”

Further benefits from ABB Preventive Maintenance include: high quality information on turbocharger performance, facilitating better care; maintenance scheduling that minimizes vessel downtime; and service always being provided by ABB’s own certified engineers and technicians. In addition, service records of all actions are always available in ABB’s comprehensive customer product database for future reference and for planning maintenance schedules.

*The full study – The Total Economic Impact of ABB Preventive Maintenance, a commissioned study conducted by Forrester Consulting on behalf of ABB – can be found at www.abb.com/turbocharging