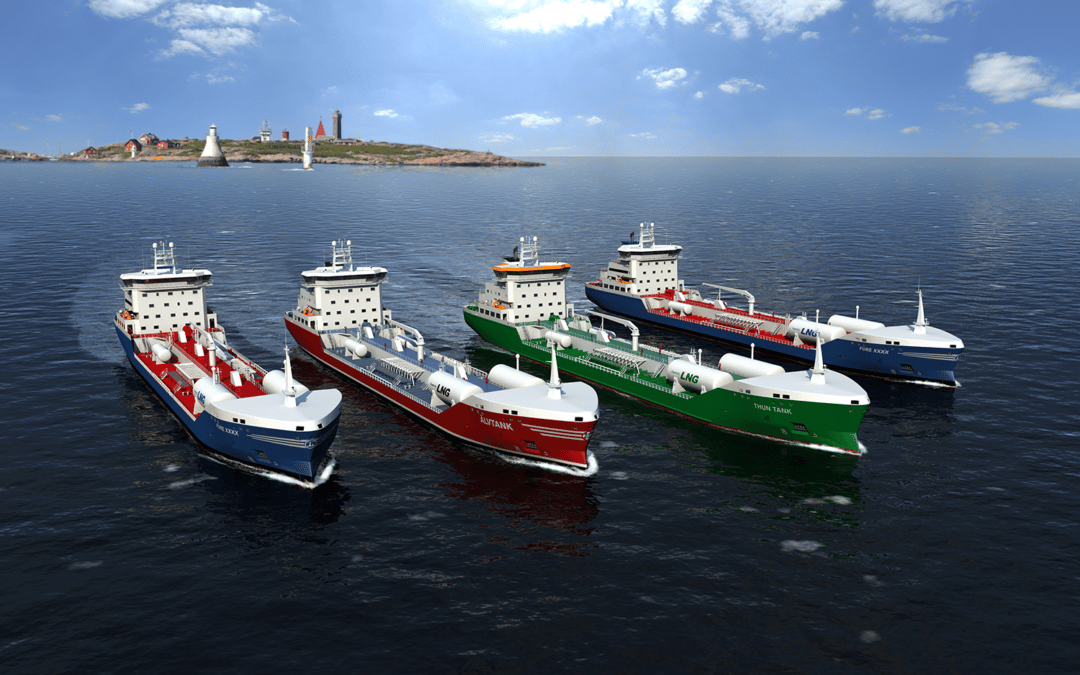

Wärtsilä has been awarded a contract covering four newbuild tanker vessels. The ships are to be built at the Avic Dingheng shipyard in China, on behalf of three Swedish owners; Furetank (2 vessels), Älvtank, and Thun Tankers, a fully owned subsidiary of Thunbolagen. The vessels will be commercially managed by Furetank Chartering in the Gothia Tanker Alliance. The contracts were signed in the second quarter of 2016.

The ships will fulfil the IMO’s Tier III requirements and will be fuelled primarily by liquefied natural gas (LNG). The scope of Wärtsilä’s supply to this project is extensive. For each vessel it comprises a 9-cylinder Wärtsilä 34DF dual-fuel main engine, two Wärtsilä Auxpac 20 auxiliary engines, the gas valve unit, a controllable pitch propeller (CPP) compliant with Ice Class 1A, a high performance nozzle, a Wärtsilä Energopac rudder system, a Wärtsilä selective catalytic reduction (SCR) system for the auxiliary engines, 12 Wärtsilä deepwell cargo pumps, and two Wärtsilä deepwell ballast pumps with a frequency control system. Wärtsilä will also supply the vessels with a gearbox and shaft alternator having ‘take-me-home’ functionality. This provides propulsion power to the auxiliary engine should the main engine be out of operation for any reason, thus allowing the vessel to return safely to port. Delivery of the Wärtsilä equipment is scheduled to commence in spring 2017.

In order to achieve optimal propulsion efficiency for these vessels, Wärtsilä utilized its OPTI Design methodology. This uses extremely accurate information via computational fluid dynamics (CFD) analysis to calculate the performance of the propeller, nozzle and rudder, including their interaction with the vessel’s hull, thereby enabling a design that gives a perfect match between the various propulsion elements.

“Wärtsilä is the only company in the world capable of providing such a comprehensive scope of marine solutions from its own portfolio. Being a total solutions provider brings significant added value to our customers since delivery and scheduling risks are reduced, and the various systems can be integrated to achieve optimal performance and lower operating costs,” says Aaron Bresnahan, Vice President, Sales, Wärtsilä Marine Solutions.

“These environmentally friendly tankers will run mainly on LNG fuel. No other company can match Wärtsilä’s experience and reference list in LNG solutions, and we are very confident that the Wärtsilä technology and broad range of solutions are the right choice,” says Lars Höglund, Managing Director of Furetank.

The vessels will be built to a design, developed by Swedish ship designer FKAB together with Furetank. They feature a special focus on minimising the impact on the environment, with a close to 50 % reduction in CO2 emissions over similar class vessels built between 2002 and 2012.