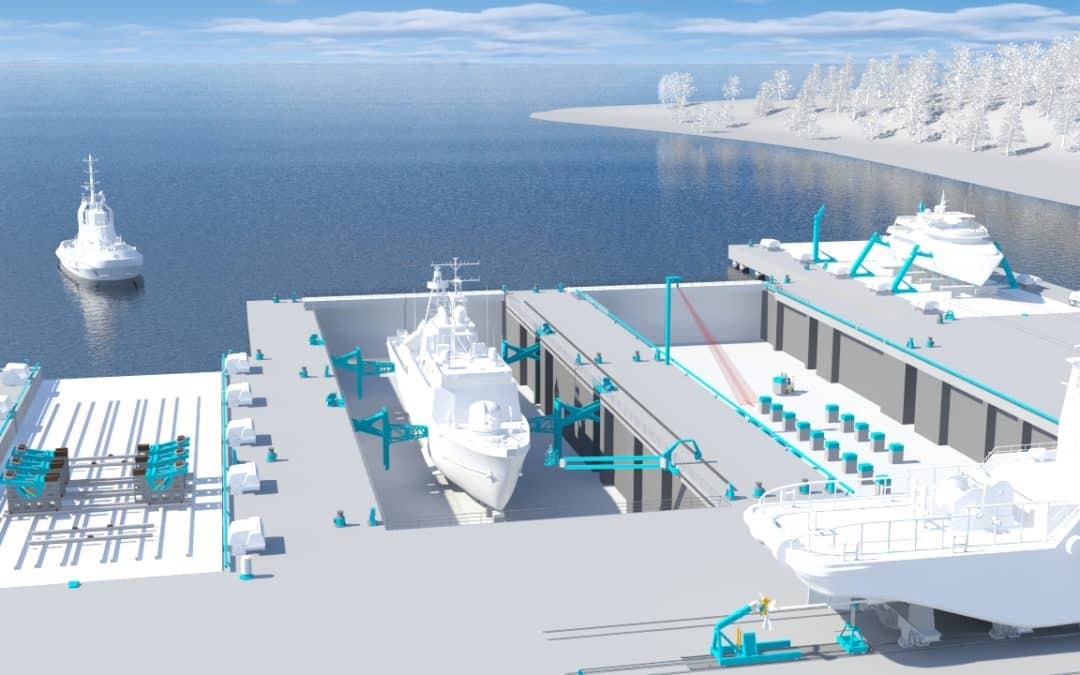

As part of a move towards improving drydocking times, TTS Syncrolift have announced they are delivering a mechanized Propeller Puller and a mechanized Multi Vessel Docking system to Norwegian and Dutch repair yards. They are also working on docking productivity projects with the Indian Navy.

The company says that, as increased competition in the 1960’s prompted newbuilding yards to improve competitiveness, repair yards can also increase efficiency.

Flow based production, with blocks continuously increasing in size, became the way forward for newbuilding yards. As assembly times for ships were reduced, the need for multiple slipways or dry docks was reduced. Syncrolift say the productivity evolution from newbuilding is relevant for repair yards. “Fast Docking” is their approach to improving productivity whilst also improving Flexibility.

The company says that blocking of vessels with a sharp keel is costly in terms of man-hours, materials and lead time. Their new solutions are said to eliminate the need for bilge blocking of ships during docking, and add to existing solutions for in-hauling ships.

A statement from TTS says: “Other pipeline products are a system for mechanizing bilge blocks positioning according to docking plan of a ship to be docked. The system will eliminate manual measuring and marking for positions of dock-blocks in the drydock. A tracker with the blocking plan will “feed” the coordinates to a fork truck operator via an operator screen located in cabin.

Another product in our pipeline – is what we call a FlexPad. The FlexPad’s will replace the wooden blocking. A set of FlexPads will last for 30-50 dockings. Not only is this a “green” approach as wood consumption is reduced, but all the logistics in changing wood is also minimized.”

See more at the TTS website here